A hole in the ground could be the future of fusion power

MIT’s startup Commonwealth has a new powerful magnet that could finally make fusion power a reality.

On an overcast day in early December, a yellow earth mover scooped dirt from the edge of a deep pit in Devens, Massachusetts, on the site of an old Army base some 50 miles outside of Boston.

This is the future home of SPARC, a prototype fusion reactor that, if all goes as hoped, will achieve a goal that’s eluded physicists for nearly a century. It will produce more energy from fusing together atoms, the same phenomenon that powers the sun, than it takes to achieve and sustain those reactions.

By some point in 2025, the scientists at Commonwealth Fusion Systems expect, their machine will blow past that threshold, generating 10 times more energy than it consumes. That demonstration, they say, will enable the startup to develop full-size facilities capable of delivering as much electricity as a small coal plant by the early 2030s.

Facilities that can harness nuclear fusion should provide a cheap source of carbon-free energy from abundant fuel sources, substantially derived from water. Crucially, fusion would generate a constant, steady stream of electricity, filling in the gaps during the hours, days, or even weeks when solar and wind sources flag. In doing so, it would simplify the path to zero-emissions electricity, eliminating the need for energy storage breakthroughs, exorbitant banks of batteries, or continued reliance on coal and natural-gas plants to keep the lights on and companies humming.

Then again, the sheer technical complexity and massive cost of achieving fusion have repeatedly dashed the hopes of scientists and hardened the stance of skeptics. The field’s best hope for a reactor that finally delivers net energy has long been ITER, an international research collaboration first conceived in the 1980s. But costs for its roughly 100-acre facility in southern France have more than tripled, rising to at least $22 billion. The project is more than a decade overdue and still years from completion. And even if ITER eventually works, its version of fusion technology could be far too costly to commercialize widely.

“The biggest pressing thing is: Can you have this ready in time to be impactful around climate change?”

Commonwealth believes it can deliver a fusion machine that is the anti-ITER: small, fast to build, and far cheaper. The prototype should cost hundreds of millions of dollars, rather than tens of billions, and take years rather than decades to construct.

The key is a novel magnet the startup has developed. The field is watching the effort particularly closely because the team has already pulled off an indisputable scientific advance by using a new type of superconducting material to build the most powerful one of its kind. In a test last September, the magnet achieved a field strength of 20 tesla. It’s nearly twice as strong as ITER’s comparable magnet, which relies on earlier superconducting materials.

Magnets can be used to confine a plasma, the ultra-hot state of matter in which fusion reactions occur. The more powerful those magnets are, the more atomic collisions, reactions, and energy you can produce within a far smaller space. A fusion device built with an array of Commonwealth’s magnets should be able to produce as much energy as one relying on ITER’s at one-fortieth the size.

Any number of challenges could still trip Commonwealth up—or at least derail its ambitious timeline. No one has yet gotten a fusion reactor to produce net energy. Commonwealth’s magnet hasn’t been tested in a working reactor. In short, fusion remains a highly experimental and unproven technology.

But there’s also hope, after decades of disappointment, that it could work. And the company and its backers, at least, believe they’re on track to deliver commercial fusion in time for it to play a significant role in the transition to carbon-free energy over the next few decades. “When we structured this whole project, around five years ago, it was always about speed,” says Dennis Whyte, director of MIT’s Plasma Science and Fusion Center and cofounder of Commonwealth Fusion.

“The biggest pressing thing is: Can you have this ready in time to be impactful around climate change?” he says. “The biggest risk is not getting there in time.”

The big hammer

Unlike coal or natural-gas plants, fusion reactors wouldn’t produce the greenhouse gases driving climate change. There’s no real risk of their running out of fuels, and there’s less of an environmental toll associated with obtaining them. And unlike its nuclear cousin, fission, fusion doesn’t require the mining or management of radioactive uranium.

Instead, Commonwealth’s machine, like most other fusion reactors, would rely on deuterium and tritium, both natural isotopes of hydrogen.

The oceans are filled with deuterium. The US Department of Energy notes that it makes up one out of every 5,000 hydrogen molecules in seawater, and that a single gallon could produce as much energy as 300 gallons of gasoline.

“The current set of renewables are good and necessary, but not sufficient to solve the climate change problem.”

Methods for extracting deuterium from water are well established and routine. Tritium, which contain two neutrons in its nucleus to deuterium’s one, is far rarer in nature, but it can be extracted from lithium.

In comparison to renewables like wind and solar, fusion could generate a lot more energy within a far smaller footprint—and it could provide an always-on source of electricity that doesn’t dip depending on the weather or time of day. Such so-called baseload power is essential to a reliable grid, and the need for it is a key reason why it’s so hard to wean the power sector off fossil fuels. “The current set of renewables are good and necessary, but not sufficient to solve the climate change problem,” says Brandon Sorbom, a cofounder and chief scientist at Commonwealth. “You need a clean baseload form of power added to that mix. We think the problem is big enough that you need this big hammer, which is fusion.”

For decades many have envisioned nuclear fission playing such a role, and many still do. But much of the public and numerous countries have turned away from it because of the high construction costs for a fission reactor, which can easily exceed $5 billion, as well as the real or perceived dangers, including fears over mounting piles of radioactive waste. In contrast, fusion poses no meltdown risks, avoiding the threat of disasters like Chernobyl, Three Mile Island, and Fukushima.

Tritium is radioactive and the fusion process releases neutrons, both of which will require rigorous safety protocols for handling the materials and eventually decommissioning the plants. But fusion doesn’t produce long-lived radioactive waste the way fission reactors do.

The hope is that the lower risks will make it faster and easier to secure regulatory approvals and construction permits, accelerating the rollout of the technology once it does work.

Here’s how fusion works

Different research groups have taken different approaches in their attempts to mimic the energy source of the sun. But they all start by generating a massive amount of heat, with temperatures in excess of 100 million °C.

Like ITER and others, Commonwealth plans to build what’s known as a tokamak reactor, a hollow doughnut-shaped device to be filled with a gas that includes deuterium and tritium atoms. The device would steadily raise the temperature by powering up those super-strong magnets, using an electric current to create resistive heating and then applying radio waves.

When temperatures rise enough, atoms begin to break apart as electrons pull away from the nuclei, creating a plasma. The electrons and positively charged nuclei move about the interior of the tokamak.

The magnets encircling the tokamak create a “magnetic bottle” that tightly contains the plasma, with higher magnetic fields significantly reducing the heat loss. On occasion, two nuclei will effectively crash into each other. The protons and neutrons will sometimes combine, forming the nucleus of a helium atom, releasing a neutron and producing a whole lot of energy.

In the sun, the heat produced from these reactions is self-sustaining, bringing about more collisions and more fusions, and on and on. But the fusion industry doesn’t necessarily have to reach that point, known as ignition, to create profitable power plants. The reactors just need to produce more output than the input required, with the exact amount depending on the underlying costs of the facility.

The general, if not quite universal, view in the field is that research groups have solved the hard scientific problems needed to produce fusion energy. Most believe that ITER will at least be able to generate a meaningful amount of net energy, once it’s finally online and operating at capacity.

But the complexity and cost of building a giant machine that can achieve these conditions has bogged down progress. Though construction on ITER began in 2007, it isn’t scheduled to be fully operational until 2035, more than a decade beyond the original schedule. And some have argued that the price tag will end up far higher than the $22 billion estimated now.

Commonwealth is using the same basic fusion science as ITER; the real difference is the magnets.

The main 11.8-tesla magnets arrayed inside ITER are built from superconducting niobium-titanium or niobium-tin materials, which require extremely low temperatures. Commonwealth takes advantage of what are known as high-temperature superconductors, which offer several key advantages. And that might make all the difference, for both the economics and the timeline.

Materials to magnets

Scientists have long known that certain materials, under certain conditions, conduct electricity with no resistance, allowing electrons to flow freely without releasing heat or losing other forms of energy in the process. That enables high currents that create strong magnetic fields around these so-called superconductors.

To get early superconducting materials like mercury and lead to reach this state, researchers had to cool them to nearly absolute zero, or around −460 °F. That required liquid helium, limiting practical applications.

But in the 1980s, researchers discovered a class of ceramics that became superconducting at far higher, though still frigid, temperatures—around −280 °F. That may not sound like a big difference, but it can be achieved with liquid nitrogen, which is much cheaper and easier to handle.

Those high-temperature superconductors can also create much more powerful magnetic fields, says Michael Sumption, associate director of the Center for Superconducting and Magnetic Materials at Ohio State University. Physicists began to dream up new technologies they thought the materials could soon deliver, like levitating trains, super-high-resolution MRIs, and very powerful magnets.

But high-temperature superconductors were extremely difficult to work with. It would take several decades before manufacturers figured out how to create long wires of the stuff, which required building highly aligned crystals and laying them out in uniform, micrometer-thin layers across a metallic substrate.

In 2009, MIT’s Dennis Whyte happened upon a colleague carrying a bundle of tape-like material through the hallways. It was an early prototype of a high-temperature-superconducting wire, made from yttrium barium copper oxide materials. Whyte immediately recognized its potential for use in fusion and assigned graduate students in one of his courses the task of designing a compact reactor that took advantage of the powerful magnetic fields the tape could produce.

The design efforts spilled over into subsequent classes and research efforts at the MIT Plasma Science and Fusion Center. In 2015, the researchers involved laid out the design of a compact fusion plant using the new materials that could produce 200 megawatts of electricity. They dubbed it ARC—the name of Tony Stark’s fictional fusion reactor in the Iron Man comics.

In 2018, the team raised tens of millions of dollars in private funding and spun out Commonwealth, which continues to collaborate closely with MIT.

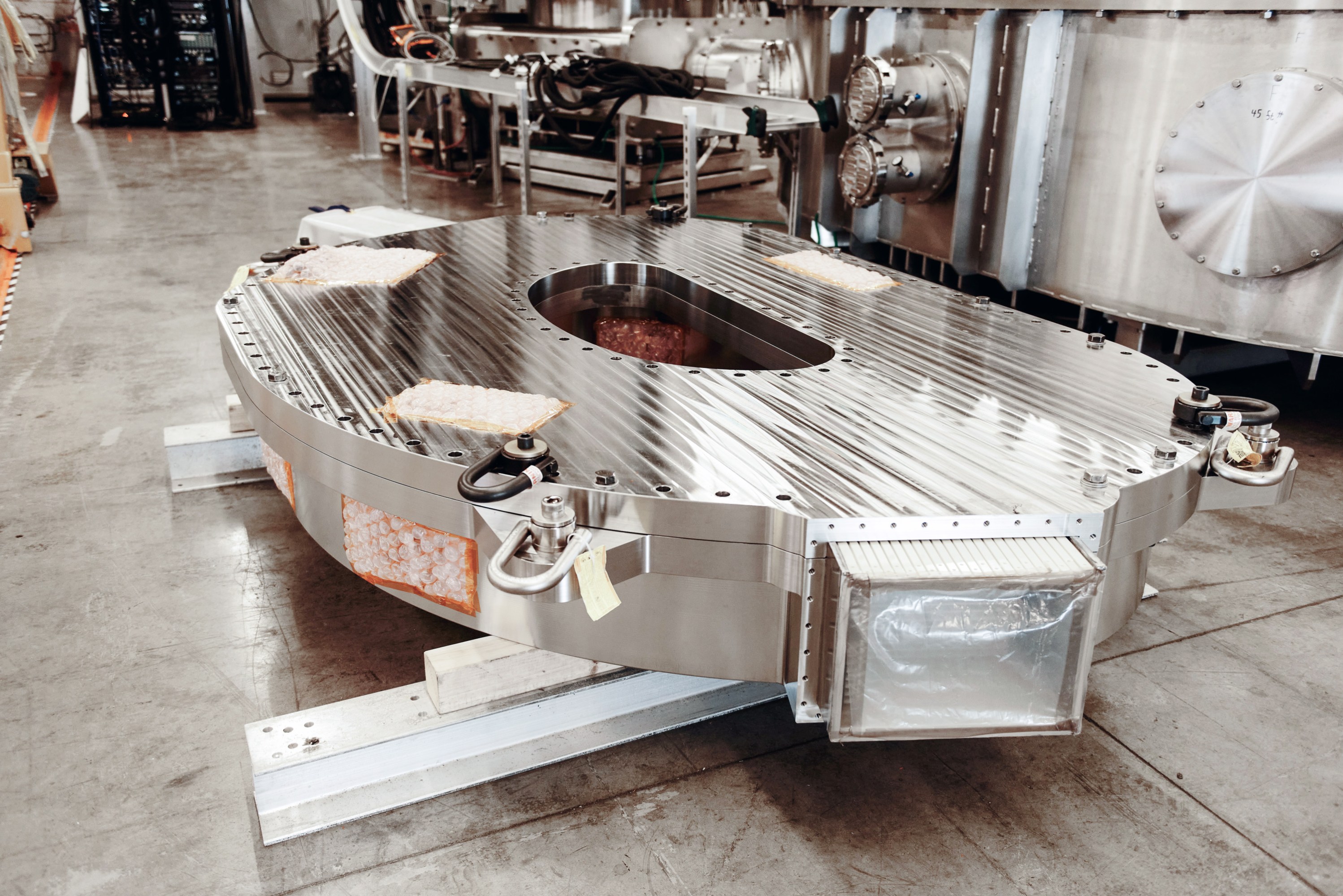

By then, high-temperature-superconducting wire was commercially available. But that was just the starting point for creating the magnet the company needed: it would have to be powerful, energy efficient, and reliable, while also designed around a big “bore,” or hole, in the middle to make space for the plasma.

The team had to work closely with a handful of manufacturers to secure an adequate supply of tape—hundreds of miles for the first magnet test alone—and optimize it for their purposes.

Once the materials met their specifications, they still needed to convert them into a giant magnet. That first required piling up layers of the thin tape into a thick, integrated stack that could carry the necessary current. In an earlier publication, the researchers described one way to do this, creating a cable by twisting and soldering dozens to hundreds of layers together.

The company declines to discuss proprietary details of how they created the stack of superconducting tape now in use. But to turn it into the test magnet, the team coiled those layers to align and boost the magnetic field, much the way you might have wrapped copper wire around a nail and connected it to a battery to create an electromagnet in elementary school. Commonwealth created 16 layers of magnets, which the researchers dubbed pancakes, each with 16 turns of the coil within them. Then they stacked those pancakes together and connected them with propriety joints, creating a 10-ton, eight-foot-tall, D-shaped supermagnet, packed with 165 miles of superconducting tape coiled around 256 times.

The test

Last summer, researchers at MIT and Commonwealth placed the magnet within an oval-shaped test stand designed to replicate the conditions of the tokamak. In late August, they began the week-long process of cooling the magnet down to cryogenic temperatures, evacuating a vacuum chamber around it, and slowly added helium under high pressure.

Once the temperatures were sufficiently frigid, the team began charging the magnet.

The scientists sat in an adjacent control room, monitoring data on screens as they pushed the magnetic fields higher and higher. Before dawn on September 5, most of the research team, as well as MIT leaders and financial backers of the startup, had assembled in the room. Around 6:00 a.m., the team finally pushed the magnet beyond 20 tesla, breaking the record for a large-bore, high-temperature-superconducting electromagnet.

“When it went past 20 tesla, nothing happened, which made me ecstatic,” Whyte says. “Nothing happened except a lot of cheering.”

SPARC, the prototype reactor that Commonwealth is now building in Devens, will include 18 of those powerful magnets, surrounding the tokamak and generating the magnetic field that will tightly contain the plasma within. A paper coauthored by the Commonwealth team in September 2020 calculated that the prototype reactor could produce as much as 11 times more energy than it consumes.

Sorbom insists that the magnet test was the major engineering obstacle Commonwealth faced. Now, he says, it comes down to execution.

“Less rosy”

Other research labs and startups are also reporting progress toward fusion. But despite the scientific advances underway, plenty of experts remain skeptical that we’ll see working commercial reactors as quickly as Commonwealth and others argue.

No lab has yet generated net energy from fusion, much less ongoing reactions that could produce cheap, consistent, reliable electricity for months.

Jessica Lovering, founder of the Good Energy Collective, a group that promotes the use of nuclear energy to address climate change, doesn’t think fusion is as imminent as some suggest. “A lot of these companies are saying they’ll demonstrate within five or 10 years,” she says. “I think that’s more of a promise to help them get investments. It’s that kind of standard tech hype we see across all kinds of technologies.”

“The promise of infinite cheap power will be a little less rosy after it arrives.”

The technology will also face regulatory challenges. The nascent industry certainly hopes that fusion reactors will prove simpler to secure permits for and build than the fission sort, which can easily take a decade.

But fusion is not risk free, says Rachel Slaybaugh, until recently a professor of nuclear engineering at the University of California, Berkeley.

Like a nuclear fission plant, a small fusion reactor could, in the wrong hands, be used to produce radioactive materials that could power weapons. And there’s still potential for serious industrial accidents given, for example, the extreme pressure differences that occur when major components of the reactor operate under a vacuum.

Even if the risks are smaller than those associated with fission, they will necessitate regulatory scrutiny and safety standards, Slaybaugh says. “After we get fusion, there may be this realization: ‘Oh, there’s still radiation and safety hazards,’” she says. She’s concerned that “the promise of infinite cheap power will be a little less rosy after it arrives.”

There are still real technical challenges ahead as well, says Edward Morse, a University of California, Berkeley, professor who studies fusion reactor design. For one, Commonwealth will still need to test how well the components hold up under the much greater stress when all 18 magnets are operating together.

“It could fail for various arcane reasons,” he says.

Morse has been critical of fusion startups, saying some are simply rehashing old ideas that Department of Energy labs gave up on—for good reasons—decades ago. But he thinks Commonwealth has a better shot than most companies in the field, precisely because it’s not taking a radically different approach to fusion.

“They’re keeping the conventional tokamak approach but replacing the magnet with something newfangled,” he says. “That’s what I like about the scheme; only one major leap at a time, please.”

Spending spree

Out at the 47-acre Devens site, near that pit where SPARC will be built, the crews have already erected the frame of a factory that will mass-produce magnets for the prototype reactor.

Commonwealth hopes to generate net power from the machine within the next three years. But the factory is designed with the capacity to produce magnets for the full-size facilities it expects to follow in the early 2030s—the ARC power plants. In those future operations, the heat energy generated would be converted into electricity through the same basic process that occurs in nuclear fission reactors or coal plants: by turning water into steam that spins a turbine.

In late November, the startup announced it had raised $1.8 billion in venture capital, providing funding to construct SPARC and begin work on the commercial facilities. The company has begun early conversations with potential customers about sites, as well as with regulators on what will be required to license and permit such plants.

“We need to assume the success of this one and figure out how to move forward,” Whyte says. “Waiting for things in serial is not going to work.”

That impatience stems from the fact that fusion power will need to be ready soon if it’s to play any major role in combating climate change.

The world needs to eliminate pollution from the power sector in the next few decades, and stop nearly all greenhouse-gas emissions by around midcentury, to have a shot at preventing very dangerous levels of warming. Meeting those goals will also mean generating much more electricity to satisfy the rising demand from plug-in vehicles as well as homes, buildings, and factories, which will come to rely more on electricity for heating, cooling, and other purposes.

To some, the hard realities of those timelines mean we can’t bank on a technology that hasn’t yet been demonstrated, much less commercialized at scale. But Lovering says that even if fusion doesn’t make it to the market before electricity is largely decarbonized, a cheap, consistent, plentiful source will still have a crucial role to play.

“The problem doesn’t stop in 2050,” she says. “We’ll still have growing energy consumption; we’ll still have countries that are rapidly growing their economies. Although fusion may be longer off, there’s still a need for it.”

Clarification: The story previously misstated the company that Rachel Slaybaugh had joined. She recently started as a principal at the investment firm DCVC.

Deep Dive

Climate change and energy

This classic game is taking on climate change

What the New Energies edition of Catan says about climate technology today.

How battery-swap networks are preventing emergency blackouts

When an earthquake rocked Taiwan, hundreds of Gogoro’s battery-swap stations automatically stopped drawing electricity to stabilize the grid.

The world’s on the verge of a carbon storage boom

Hundreds of looming projects will force communities to weigh the climate claims and environmental risks of capturing, moving, and storing carbon dioxide.

The cost of building the perfect wave

The growing business of surf pools wants to bring the ocean experience inland. But with many planned for areas facing water scarcity, who bears the cost?

Stay connected

Get the latest updates from

MIT Technology Review

Discover special offers, top stories, upcoming events, and more.